Laser blade lights are ultra-slim linear luminaires used to create razor-thin lines of light for ceilings, coves, façades, and accents. This guide explains the types (recessed, surface, suspended, and outdoor), critical specifications (lumens/m /m, beam, CRI, and driver), Delhi-specific buying tips (dust, heat, and power spikes), installation, and maintenance, so buyers — including architects, contractors, and homeowners — can specify correctly.

1. Why Laser Blade Lights are trending in Delhi

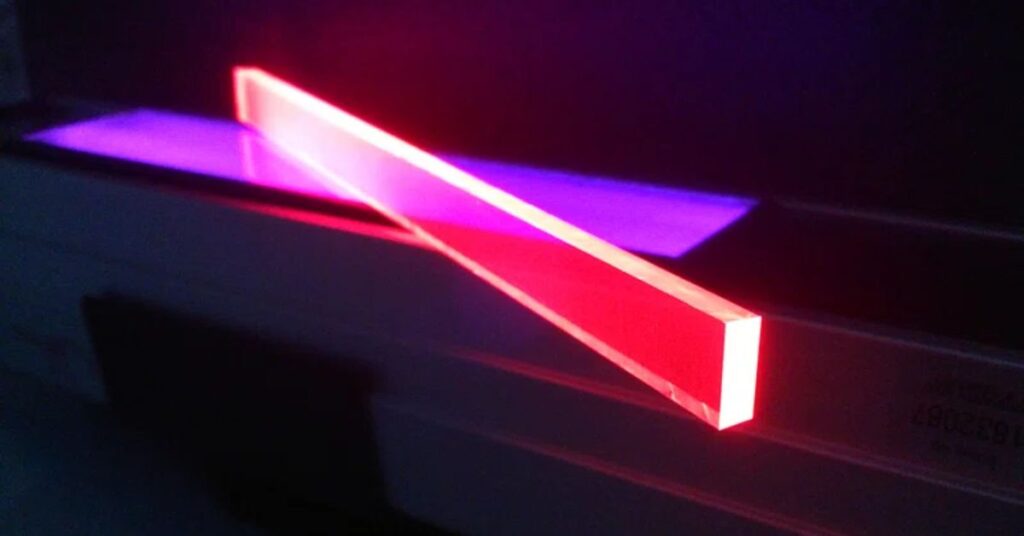

Minimal, precise, and visually striking — laser blade lights (also called blade lights, razor-edge linear fixtures, or ultra-slim linear LEDs) have become a go-to element for modern interiors and architectural façades. They create clean lines of illumination that define geometry, highlight transitions, and produce dramatic backlit effects without visible hardware. In Delhi, where contemporary retail, hospitality, and premium residences demand elegant lighting solutions, laser blade lights deliver a big aesthetic impact in a small form factor.

But choosing the right blade light is more than picking a thin profile. Thermal performance, driver quality, optics, IP rating, and installation details determine whether your razor line remains uniform, glare-free, and durable in Delhi’s dusty, hot environment. This guide covers everything a new buyer needs — from technical specs and design use-cases to installation checklists, maintenance, and local purchasing tips.

2. What are Laser Blade Lights?

Laser blade lights are linear LED luminaires characterized by extremely narrow visible profiles — sometimes just a few millimetres of sightline — that emit either direct light (downwards) or indirect light (backlit into a ceiling/wall slot). They are designed to create continuous linear illuminance with minimal visible housing. Common implementations include:

- Recessed blade slots (trimless, flush with plaster)

- Surface-mounted mini-profiles (slim, low-protrusion)

- Suspended blade bars (thin suspended elements)

- Outdoor blade façades (sealed, narrow-profile façade washers)

Their hallmark is a crisp, uninterrupted line of light suitable for modern architectural language.

3. Types & styles

Recessed trimless blade

- Installed within a ceiling or wall slot, so only a thin slit of light is visible. Best for premium interiors where seamless aesthetics are needed (hotel lobbies, galleries).

Surface-mounted mini blade

- Ultra-low profile body fixed to the surface. Ideal for retrofit projects with limited ceiling depth or where a subtle reveal is desired.

Suspended laser blade

- Thin bars hung by cables or rods. Works well above reception desks, long tables, or as a rhythmic architectural element in retail and offices.

Backlit cove blade

- Blade illuminates a cove or recess, producing an indirect glow. Great for soft ambient effects and perimeter treatments.

Outdoor façade blade

- Narrow, sealed fixtures with narrow-to-medium beam optics to emphasize edges or vertical joints on building façades. Must be IP65+ and corrosion resistant.

Pixel or RGB/RGBW blade

- Addressable segments for dynamic colour effects. Used for signage, dynamic façades, or theatrical installations.

Flexible/segmented blades

- For slight curves or segmented continuous runs where straight rigid profiles are not feasible.

4. Technical specs explained — what actually matters

Buying laser blade lights requires attention to specific metrics — here’s what each means and a recommended range for Delhi projects.

Visible sightline (mm)

- What: The apparent width of the light slit. Laser blades often have 2–12 mm sightlines.

- Choose: 2–6 mm for the “laser” aesthetic; 6–12 mm if you need slightly more brightness or diffuser area.

Lumens per metre (lm/m)

- What: Brightness along the run. Blade lights are rated in lm/m.

- Recommendation:

- Ambient perimeter/indirect: 800–1,200 lm/m

- Accent/task: 1,200–2,200 lm/m

- High-bright retail or façade accents: 2,200–3,500 lm/m

Efficacy (lm/W)

- What: Efficiency (lumens produced per watt). Higher means lower running cost.

- Choose fixtures with ≥100 lm/W; premium drivers and LEDs can exceed 140 lm/W.

Beam control & optics

- What: Blade optics shape the spread — narrow batwing for even wall/perimeter wash, asymmetric optics for specific angles. Micro-optic diffusers and opal covers help avoid seeing individual LEDs (no “dots”).

- Tip: For a true continuous line, use either micro-prismatic diffusers or high-density LED engines with continuous diffusers.

CCT — Correlated Colour Temperature (K)

- What: Warmth of the light.

- Recommendation: 2,700–3,300K for warm interiors; 3,300–4,000K for retail/offices. Consider tunable white (2700–6500K) for flexible scenes.

CRI / TM-30

- What: How accurately colours render. CRI ≥80 is baseline; CRI ≥90 is strongly advised for retail, hospitality, and material-showcase areas. TM-30 metrics are helpful for advanced color fidelity.

Bin matching & colour consistency

- Very important for long runs: ensure all LEDs are from the same bin/batch to avoid visible colour steps.

Driver type & dimming

- Choose high-quality constant-current drivers with dimming options: TRIAC (legacy), 0–10V, DALI/DALI-2, DMX for pixel control, or modern smart drivers (KNX/Zigbee). For commercial projects, DALI-2 is recommended for precise zone control.

Power factor (PF) & THD

- PF > 0.9, THD < 20% recommended to reduce disturbances to building electrical systems.

Thermal management

- Blade profiles have limited surface area — heat must be managed. Select aluminum extrusions with good thermal contact and drivers rated for enclosed conditions. Poor thermal design shortens LED life and shifts colour.

Lifetime & LM figures

- Look for LM-80 test data and lifetime claims like L80 @ 50,000 hrs (80% lumen maintenance after 50k hrs). Prefer vendors who provide test certificates.

IP rating & sealing

- Indoor: IP20 acceptable. Outdoor/exposed: IP65 / IP66 for dust and water resistance. For semi-exposed soffits, choose IP54+.

IK rating & mechanical robustness

- Public areas may require IK08 or higher for impact resistance.

Mounting tolerances & slot dimensions

- Recessed blade needs precise slot width and drywall/plaster tolerances. Get manufacturer cut-out drawings and allow tolerance for plaster thickness and paint.

Certifications & warranty

- Check BIS/CE/RoHS and ask for warranty split: LEDs, driver, and profile (e.g., 3 years on driver, 5+ years on LED modules).

Surge protection & voltage tolerance

- Delhi has occasional spikes. Ask for surge protection (e.g., 1–2kV) on drivers or external surge protection devices.

5. Design & application use-cases

Perimeter ceiling slots — creates floating ceilings with crisp light lines; ideal for high-end living rooms, hotel lobbies.

Feature lines & reveals — used as visual dividers, marking circulation paths, or highlighting architectural joints.

Retail gondolas & display trims — razor lines over shelving deliver clean product separation.

Worktops & desks (suspended) — thin suspended blades over benches provide minimal visual clutter with task illumination.

Façade edge lighting — narrow blades to accent horizontal/vertical joints, cornices, or parapets on commercial buildings (use outdoor-rated fixtures).

Backlit signage & cove indirect — blades recessed into coves for soft ambient glow without visible source.

Dynamic façades/pixel installations (RGB or pixel-addressable) — create moving patterns or branding effects on exteriors and stages.

Typical lux guidelines (examples):

- Ambient/indirect: 100–200 lux

- Task/accent: 300–600 lux at the working plane or display face

- Façade accents: depends heavily on distance and desired contrast — photometry required

6. Buying guide for Delhi — practical checklist

1. Environment & durability

- Delhi’s dust and heat demand sealed solutions for exposed areas. Indoor slots that open into dusty plenum spaces should have sealed fittings or easy-to-clean diffusers.

2. Thermal & power considerations

- Blade lights often have compact heat paths. Choose fixtures rated for enclosed or high-temperature installs if ceiling cavities are hot. Use drivers with wide input voltage ranges and surge protection.

3. Samples & mockups

- Always request a 1–2 m sample run and on-site mockup for colour, glare, and continuity checks. Small differences in binning or diffuser type become obvious at scale.

4. Controls & integration

- For offices/retail, specify DALI/DALI-2 or compatible smart drivers. For pixel effects, confirm DMX or L-protocol compatibility.

5. Service & spares

- Buy from vendors offering local driver spares, diffuser sections, and exchange programs. Mark runs segments during installation for quick replacements.

6. Budget tiers

- Economy: LED strip in generic channel (visible dots, lower binning) — good for low-budget retrofit.

- Mid-range: Integrated modules with continuous diffusers, decent binning, and basic dimming.

- Premium: High-density LED engines, precise optics, CRI ≥90, tunable white, DALI-2, extended warranty, and photometric support.

7. Documentation

- Insist on IES/IESNA files, cut-out drawings, MDH (mount distance to height) tables, LM-80/LM-79 reports, and driver datasheets.

7. Installation & mounting

Recessed laser blade (trimless)

- An accurate slot template and a rigid frame are required. Install frame or extrusion first, route driver and control cables before plastering, then fit diffuser post-finish. Maintain precise slot width tolerance.

Surface-mounted mini blade

- Mount bracket to substrate, ensure level runs, route drivers (remote or onboard), seal per manufacturer instructions.

Suspended blades

- Rig anchors for cables/rods, suspend and level, and protect cable routing inside the canopy for power and control wiring.

Outdoor façade blades

- Use stainless fixings, sealed cable glands, provision for drainage; place drivers in weatherproof enclosures or accessible cavities. Include surge protection and maintenance access.

Wiring & safety

- Always use qualified electricians, correct cable gauge, labelled control lines, and earth continuity. For commercial builds, separate emergency circuits and testing per code.

8. Maintenance, troubleshooting & warranty

Cleaning: Dust builds quickly in Delhi — monthly light dusting and quarterly soft wash for diffusers. Use microfiber and mild detergent; avoid solvents that could haze diffusers.

Maintenance checks: Annual driver temperature checks, visual colour uniformity inspection, and secure fastener verification for suspended runs.

Troubleshooting:

- Uneven line: check diffuser seating, LED module failures, or incorrect mounting tolerance.

- Flicker: driver or control signal issues — swap driver to isolate.

- Colour shift: mismatched bins or heat-stress — replace in matched batches.

Spares & documentation: Keep spare drivers and 1–2 spare linear sections. Maintain installation maps showing driver locations and segment IDs. Keep invoices, IES files, and serial numbers for warranty claims.

9. FAQs

Q1: How thin can a laser blade light be?

A: Visible sightlines commonly range from ~2 mm to 12 mm. Ultra-thin “laser” looks are 2–6 mm but need careful optics and high-density LEDs.

Q2: Can blade lights be used outdoors in Delhi?

A: Yes — choose IP65/66 rated outdoor blades, stainless fixings, sealed glands, and surge protection for driver circuits.

Q3: Why do long runs sometimes show colour banding?

A: Colour banding occurs from mixed LED bins, different batches, or inconsistent drivers. Specify bin-matched LEDs and buy runs from the same production batch.

Q4: Are laser blade lights dimmable?

A: Yes, with compatible drivers. For commercial installs, use DALI/DALI-2 for best control.

Q5: How do I avoid seeing LED dots?

A: Use high-density LED modules plus continuous diffusers (micro-prismatic or opal) and correct spacing to create a uniform line.

Q6: What is the typical lead time for custom blades?

A: Varies by manufacturer and finish; custom lengths, finishes, and IP ratings add to lead times. Always confirm before project scheduling.

Q7: How long do these lights last?

A: Quality LED engines with proper thermal design achieve 50,000+ hours (L80/L70 ratings). Driver life is a common limiting factor.

Q8: What should I ask my supplier in Delhi?

A: Ask for IES files, LM-80/79 data, bin codes, driver spec (PF/THD), IP/IK ratings, warranty split, local service, and sample/mockup.

10. Conclusion & Call to Action

Laser blade lights deliver a refined, modern aesthetic with powerful design flexibility — from razor-thin ceiling slots to dramatic façade accents. For success in Delhi, prioritize proper thermal design, high-quality drivers, bin-matched LEDs, and IP/IK ratings where needed. Want to test a real sample or get on-site photometric mockups? Visit Agarsain Bath & Lights (The Lantern) for product samples, IES files, and professional lighting consultation — or request an on-site demo today.